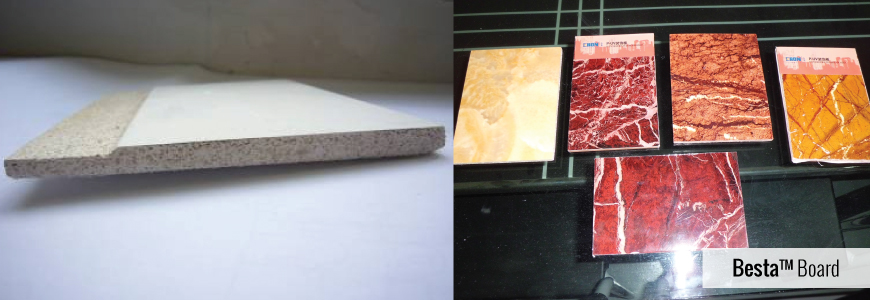

Besta Wall and Floor Boards and Panels

Besta Board Properties

| Density Kg/m3 Nominal | 950 to 1200 kg/M3 |

| Tensile Strength Mpa Minimum | 5Mpa |

| Bending Strength Mpa Minimum | 9Mpa-16Mpa |

| Thinkness Tolerance Ln m m | ±0.5 |

| Specific Absorption Ratio Maximum in % | 22% |

| Moisture Distortion Rate Maximum in % | 0.34% |

| Sustained Combustion Time in % | 0% |

| Length Tolerance in mm | ±4 |

| Shock Strength KJ/m2 Minimum | 5.5KJ/M2 |

| Thermal Conductivity W/m K Maximum | 0.132W/mk |

| No Asbestos Content | |

| Flatness in m m | 2mm |

| Temperature Shrinkage Rate in % Maximum | 0.1% |

| Fire Redundancy (Non-Combustible A Grade) | A Grade |

| Minimum Bending strength Mpa | 10.5Mpa |

Besta Chemical Compositions

| Substance Name | Properties | Proportion(by weight) |

| Magnesium Oxide | Non- hazardous | 65% |

| material for shipping | ||

| Magnesium Chloride |

Non- hazardous | 25% |

| material for shipping | ||

| Fiberglass non-woven mesh |

Non- hazardous | <10% |

| material for shipping | ||

| Talc | Non- hazardous | <5% |

| material for shipping | ||

| Other non hazardous ingredients (fillers) |

Non- hazardous | <5% |

| material for shipping |

Master Test Result Summaries on BESTA Mgo Board & Panel System A) Test Results on Material Property (10mm thick & 16mm thick Mgo boards ) (Updated on 12th January 2009

| S/N | Type of Test | Clause,Methods | Besta Mgo Board(10mm thick) | Besta Mgo Board(16mm thick) |

| 1 | Density | Cl.6.3,ISO TR 1896 | 1060kg/m3 | 1030kg/m3 |

| 2 | Bending Strength (Dry and Saturated) | Cl.6.4,ISO TR 1896 | 5.5N/mm2(Dry);6.0N/mm2(Saturated) | 10.1N/mm2(Dry);9.5N/mm2(Saturated) |

| 3 | Linear Thermal Shrinkage | Cl.6.7,ISO TR 1896 | Samples softened &crumpled after subjected to 950℃ for 4hrs | Max.shinkage:-2.2%; Max.expansion:+2.3% after subjected to 950℃ for 4 hrs |

| 4 | Moisture Movement | Cl.8,ASTM C 1185 | 0.08% | 0.21% |

| 5 | Water Absorption | Cl.9,ASTM C 1185 | 22.00% | 21.60% |

| 6 | Moisture Content | Cl.10,ASTM C 1185 | 9.60% | 7.50% |

| 7 | Water Tightness | Cl.11,ASTM C 1185 | Dampness appeard after 5 hours | Withstand 50mm water head without sign of dampness at bottom suface after 24 hours |

| 8 | Non-Combustibiltiy | BS 476:Part4 | Non-combustible material | N.A |

| 9 | Thermal Conductivity | ASTM C518 | 0.132 W/m k (300*300*10mm) | N.A |

| 10 | Thermal Conductivity | ASTM C518 | 0.133 W/m k (300*300*100mm sandwich panel) | |

| 11 | Thermal Conductivity | ASTM C518 | 0.196 W/m k (600*600*128mm sandwich panel) | |

(Netional Research Center of Testing Techniques for Building Materials)

Report No.:200531703

| No. | Test Item | Standard Index(qualified product) | Test Result | Judge | |

| 1 | Bending strength ,Mpa | ±14 | 15.8 | pass | |

| 2 | Tensile strength ,Mpa | ≥5 | 5.4 | pass | |

| 3 | Water absorption ,% | ±28 | 20.9 | pass | |

| 4 | Aqueous alkali out resistance | No water and no dampness | No water and no dampness | pass | |

| 5 | Impacting strength ,KJ/m2 | ≥1.9 | 5.1 | pass | |

| 6 | Fire retardaney(A grade) |

average exotherm in furnace,℃ | ±50 | 7 | pass |

| sustained combustion time,s | ±20 | 0 | pass | ||

| mass loss,% | ±50 | 41 | pass | ||

| 7 | Apparent density ,t/m3 | ≤1.5 | 0.93 | pass | |

| 8 | Frost-resistance | 25 times circuations later,Node larm inations and no chaps | No delam inations and no chaps | ||

| 9 | Moisture content ,% | 14.8 | |||

| 10 | asbestos content | no asbestos fbers | no asbestos fbers | ||

Remark

The tests of Frost-resistance are carried out according to GB/T 7019-1997

The Test of asbestos content is cattied out according to HBC19-2005

Fire & Acousitc Rating Reference

| Item | Fire-proof Limit | Front Thickness | Back Thickness |

| Steel-column Wrapping | 2h | 12mm | 12mm |

| 2-2.5h | 12mm | 12mm | |

| 3h | 15mm | 15mm | |

| Steel-beam Wrapping | 1.5h | 10mm | 10mm |

| 2h | 10mm | 12mm |