Besta Meterials and Manufacture

Besta boards are made as individual pieces that are cut to length as they are poured onto a casting tray. The initial set occurs horizontally.

However the final cure occurs vertically or with spacers between the sheets in the steam cure chamber. The Besta is cast in a liquid slurry-like form (a mixture of MgO2 powder, Magnesium Chloride and other additives).

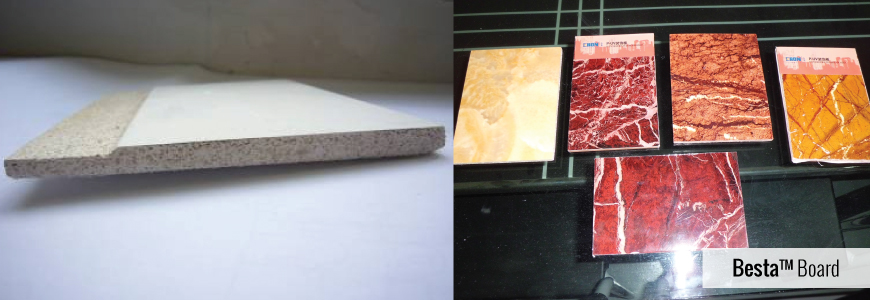

The cast boards are then cured at curing chamber temperature. Besta Board is manufactured by combining the various minerals together with high strength fibrous reinforcements. Since Besta is manufactured from mineral components, it does not contain any organic solvent, asbestos, oil or toxic component, nor any heavy metal salts. No energy is consumed in the manufacturing process since the entire process is completed at room temperature. All manufacturing excess may be reground and reused for subsequent production.

Dust and sawdust may be safely buried in landfills; it is non-toxic and will not cause contamination to the surrounding areas or environmental damage. Besta fireproof boards have primarily been used as finishing materials to walls and ceilings in offices, shopping centre, private apartments, condominiums, airports, hotels, theatres, restaurants, private institutions, universities, schools, hospitals, sports complexes, stadiums, etc. Some patterned products have been selected and used as decorative boards.

Magnesium Oxide boards are primarily used as wall-board alternative to conventional gypsum-based drywall. The boards can be scored and snapped, sawed, drilled, and fastened to wood or steel framing. It can be used for interior or exterior applications. Magnesium oxide boards are a good example of the advances made in construction materials to meet changes in building codes for safety and durability.